A City-wide SCADA Upgrade in Pearland, Texas

The City of Pearland’s Supervisory Control and Data Acquisition (SCADA) system manages water and wastewater operations, but it naturally became outdated and less efficient since the original infrastructure was put in place. Aging technology added to the City’s goal to seek out a modern, streamlined SCADA solution that could support its operations and the growing needs of the region.

a new city-wide scada system

The City teamed up with CDM Smith’s team of automation experts to design and implement a new city-wide SCADA system to replace the outdated platform. The previous system lacked effective remote control and monitoring, and this led to more maintenance and difficulties in troubleshooting. To effectively jumpstart the system’s transformation, the team began with comprehensive condition and risk assessments, followed by selection workshops to determine the appropriate programmable logic controller (PLC) and SCADA platforms.

Establishing a single city-wide standard for PLCs and human-machine interfaces (HMI) was another early step in the process of upgrading the system. The team based this standard on VTSCADA by Trihedral and CompactLogix PLCs by Rockwell Automation. Other software, like TopView for remote alarms and XLReporter for automatic reporting, was integrated to boost system performance.

three project phases to align with annual budget

Phase 1: focused on creating the conceptual design report (CDR) after condition and operation workshops

Phase 1: focused on creating the conceptual design report (CDR) after condition and operation workshops

Phase 2: involved final design, programming, and commissioning SCADA standards at the city’s 10 water treatment plants

Phase 3A: saw the SCADA system rolled out at 15 lift stations and the Reflection Bay Water Reclamation Facility (WRF), which CDM Smith expanded in 2017

Phase 3B: finalized design, programming, and commissioning for 33 more lift stations

The team used the progressive design build approach to meet the client’s needs by phasing the work prioritizing functionality that met their budgetary parameters. Client engagement was also maintained throughout each phase through workshops and technical meetings to customize their SCADA program. This close collaboration allowed site specific solutions to be developed and implemented readily without the need for lengthy negotiations or delays.

elevating operational efficiency

The new SCADA system replaced the old site-based architecture with a fully redundant and virtualized system hosted across two separate locations. This created a more resilient and reliable system, and each remote site (like water plants and lift stations) has a local server that can operate independently during network outages to guarantee continuous local control and data collection. The system can also connect to five servers for uninterrupted communication even during disruptions. Enhanced security is managed by the City’s IT department, ensuring safe access from any authorized location.

The new SCADA system replaced the old site-based architecture with a fully redundant and virtualized system hosted across two separate locations. This created a more resilient and reliable system, and each remote site (like water plants and lift stations) has a local server that can operate independently during network outages to guarantee continuous local control and data collection. The system can also connect to five servers for uninterrupted communication even during disruptions. Enhanced security is managed by the City’s IT department, ensuring safe access from any authorized location.

The risks of system failure and downtime have been cut down with the implementation of built-in redundancies, and consistent standards across facilities make maintenance and future upgrades much easier for the City. Remote alarms and automated reporting improve operational efficiency, and the new virtualized system reduces the physical footprint of SCADA servers while giving remote sites more control.

In the long term, these improvements are expected to reduce operating costs, enhance reliability, and ensure that Pearland's water and wastewater services are future ready.

I'm inspired by working with clients to identify their organizational vision and developing a customized technology plan that helps them achieve that vision.

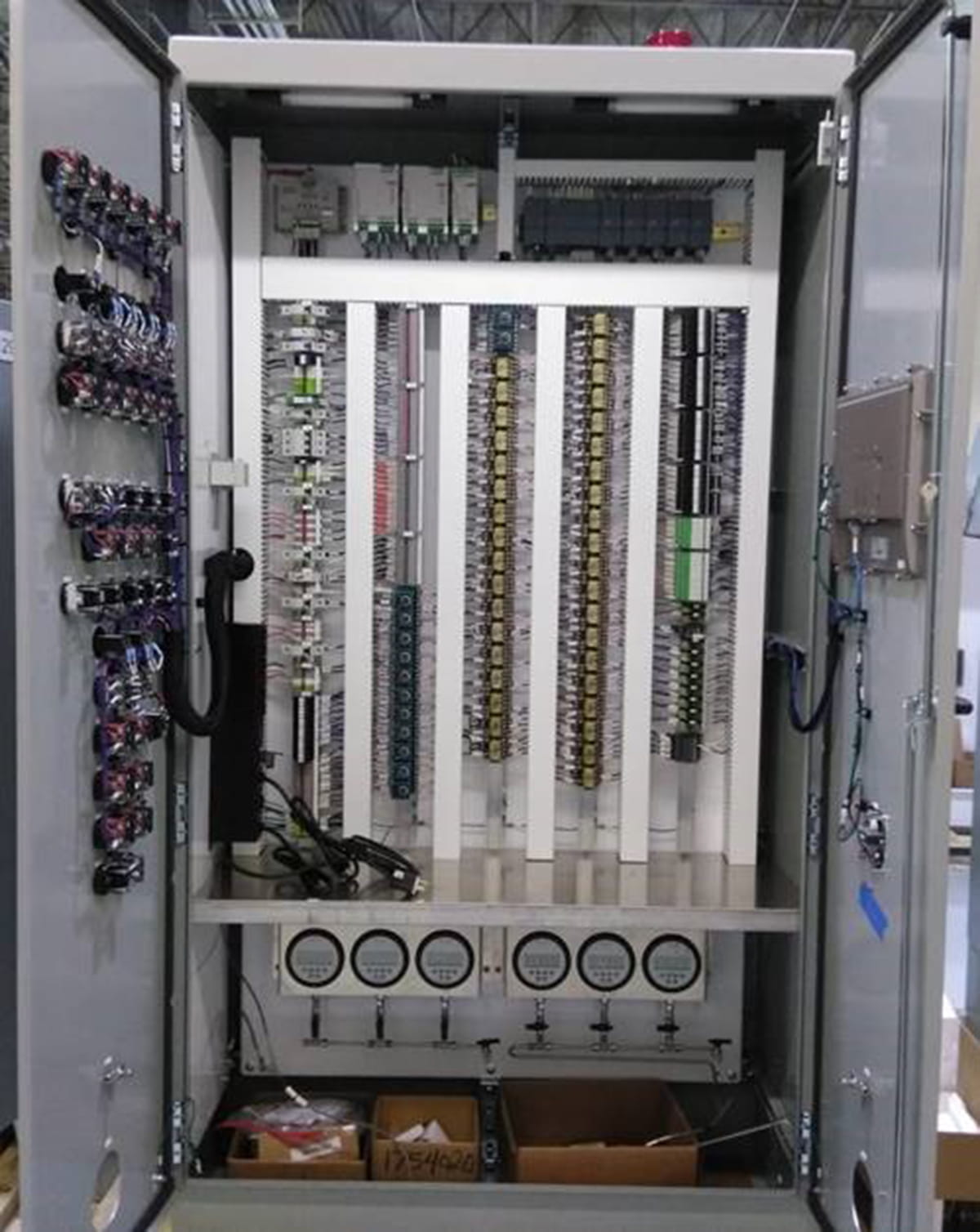

CDM Smith has a UL508A control panel fabrication facility in Bryan/College Station, Texas that makes custom control and instrumentation panels and assemblies to meet each project's specific needs, like size, mounting, environment, materials, accessories, and rating.

The fabrication shops offer design flexibility, allow for changes in scope and project schedules, and most importantly for clients, help control costs, ensure quality, and reduce the risk of project delays.