AFFF Cleanout: Essential Guidance for Fluorine-Free Foam Transition

“There was never really a reason to contain Aqueous Film Forming Foams (AFFF), because everyone thought it was similar to soap,” says Jill Greene, CDM Smith principal and an expert in hazardous waste and hydrogeologic investigations.

Since the late 1960s, AFFF became ubiquitous as a highly effective firefighting tool. Today, they are a common cause of PFAS contamination throughout the world.

“How do you decontaminate people and equipment that have come in contact with AFFF?” said Greene. “No one has really had to do this before.”

F3 Transition

On Jan. 6, 2023, the U.S. Department of Defense (DoD) released new military specifications for firefighting foams. Under the new U.S. military specifications, operators at U.S. military sites, U.S. commercial airports and other businesses now have access to fluorine-free firefighting (F3) foams, which can effectively extinguish fires without the use of PFAS.

However, there is currently no standard practice for effectively removing PFAS compounds from pumps, tanks, trucks and hangar fire suppression systems. Individual components, if not the entire foam delivery system, may need to be replaced to be compatible with the new product.

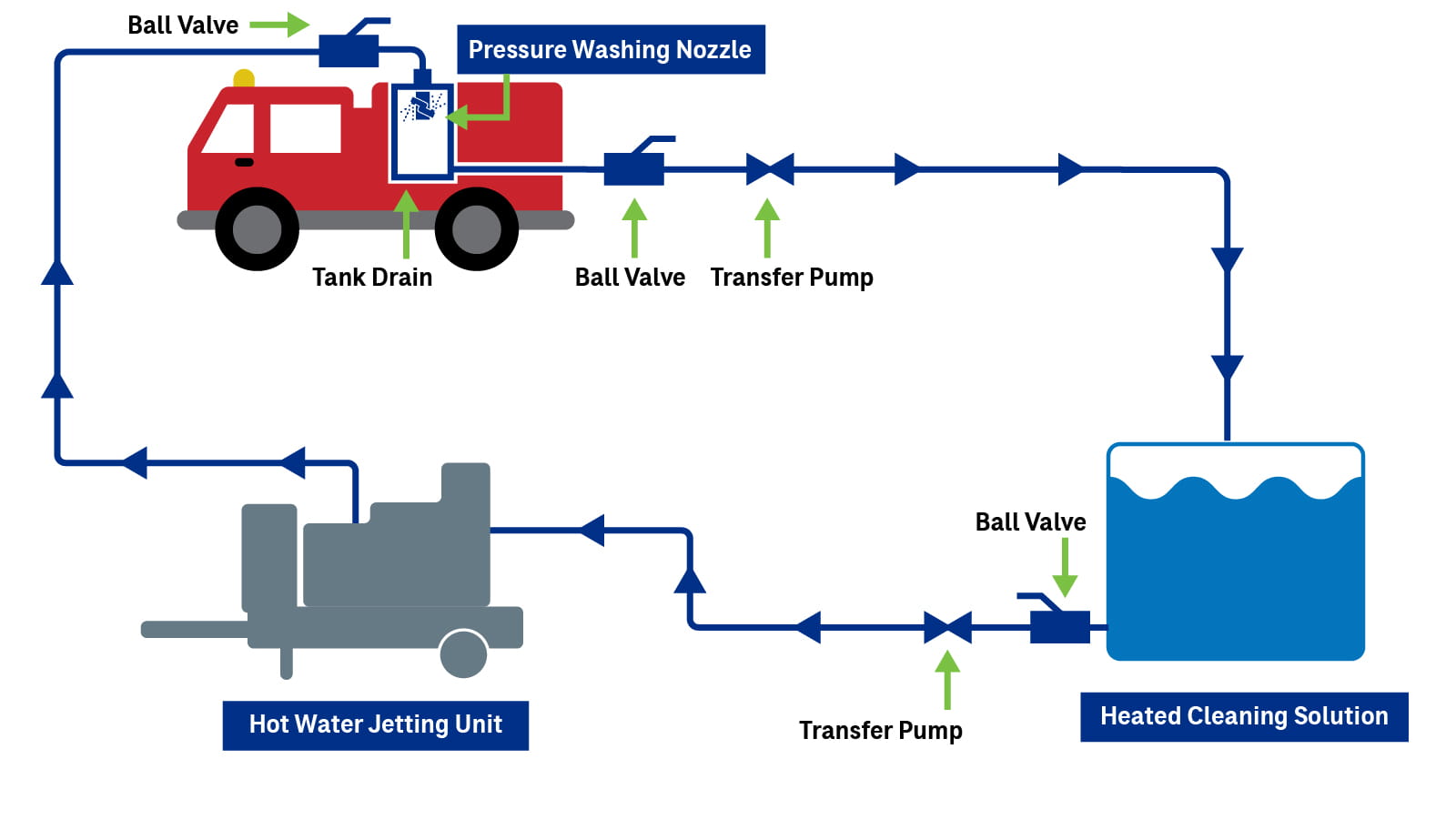

With new information on how AFFF can linger within aircraft rescue and fire-fighting vehicles (ARFF), our experts have piloted a new method of cleanout.

Fate and Transport

The DOD has completed thousands of investigations of potentially contaminated sites at more than 700 active military installations, with many more investigations on the horizon to implement remediation programs. The current challenge faced by the DOD is to analyze all of the data to develop short- and long-term effective remediation programs.

Dr. Charles Schaefer, head of the Bellevue Testing and Research Laboratory has been leading research to assess and validate analytical tools that provide information critical to overall PFAS mass discharge, perfluoroalkyl acid formation potential and organic fluorine mass balance. Research teams at CDM Smith continue to study the behaviors of PFAS in the environment and search for new treatment solutions, working with agencies like the Water Research Foundation (WRF), as well as Department of Defense agencies like the US Air Force Civil Engineer Center (AFCEC), as well as SERDP and ESTCP:

- PFAS Leaching at AFFF-Impacted Sites: Insight into Soil-to-Groundwater Ratios

- Characterizing PFAS in Groundwater: Assessment of Tools and Fluorine Balances

- Investigating Electrochemical and Reductive Approaches for Treatment of Perfluoroalkyl Substances in Groundwater

- Tools and Sensors for Characterizing PFAS Source Zones

Their research over the past several decades have led to a more comprehensive understanding of how PFAS and AFFF migrate through our environment. Recent discoveries have led to more efficient and effective cleanout processes.

CDM Smith is at the forefront of understanding contaminants like PFAS and how we can mitigate their impacts to sensitive receptors.

Treatment

The latest health advisories for PFAS call for extremely low levels, measured in the parts-per-trillion. That means an increased likelihood of aggressive remediation of PFAS from discharges of AFFF to the environment, down to an almost non-detectable level.

Only the most aggressive and energy-intensive technologies are capable of breaking down PFAS. Therefore, cost-efficient treatment options for large volumes of contaminated water rely on coupling technologies that first separate and concentrate PFAS to reduce the volumes and make destructive treatment technologies viable.

It is important to take a physical tour of your facilities and record all products that can potentially pollute the environment upon release. Develop a foam inventory and stock tracking system documenting the foam composition, brand, and manufacturer. “The first step of a prevention plan is knowing what you need to prevent,” Greene says. “Document what you have and get rid of anything expired or obsolete.

It is important to take a physical tour of your facilities and record all products that can potentially pollute the environment upon release. Develop a foam inventory and stock tracking system documenting the foam composition, brand, and manufacturer. “The first step of a prevention plan is knowing what you need to prevent,” Greene says. “Document what you have and get rid of anything expired or obsolete.

Eliminate the use of AFFF products and other fluorinated “Class B foams for training and testing of foam systems and equipment” whenever possible. Provide containment, treatment, and proper disposal of foam solution. Avoid direct release to the environment to the greatest possible extent.