Turning to the Right During Downturns

Facing oil and gas price volatility, upstream operators have been asked to constantly evaluate and reduce capital and operating, or CAPEX and OPEX, costs over the last few years. The efficiencies and lessons they have learned during market downturns have created a “new normal” that oil and gas businesses can emulate when the market rebounds. Here are some suggestions and examples for how operators can "turn to the right" (as the well-known drilling phrase goes) during downturns to effectively manage infrastructure development and water management costs and demands:

- Focus on projects that deliver a return on investment in less than 18 months. CDM Smith helped one developer realize this goal through the design and construction of water transfer facilities with a throughput capacity of up to 15,000 barrels per day (bpd) of produced fluids. These enhanced collection and recovery facilities reclaim up to 150 bpd of saleable skim oil, resulting in facility payback in less than 13 months. The facilities also reduce the need for ongoing gas flaring and related costs.

- Identify dual-purpose projects that simultaneously reduce water demands and costs. In the Permian Basin, we designed and built impoundments to store and reuse produced water for unconventional drilling activities. These storage facilities dramatically reduced fresh water demands and costs for the owner, while simultaneously reducing the costs of off-site water transportation and disposal.

Develop cost-effective water management programs. Incorporating brackish water into drilling programs helps reduce demands on fresh water stems and alleviates lantern pressure on public domain water supplies. For one client, CDM Smith designed and constructed four high-volume brackish water supply wells that will provide source water needed for future drilling and completions activities. Reducing freshwater purchases will offset the cost of constructing the wells within the first 3 months of use.

Develop cost-effective water management programs. Incorporating brackish water into drilling programs helps reduce demands on fresh water stems and alleviates lantern pressure on public domain water supplies. For one client, CDM Smith designed and constructed four high-volume brackish water supply wells that will provide source water needed for future drilling and completions activities. Reducing freshwater purchases will offset the cost of constructing the wells within the first 3 months of use.- Apply asset management strategies to plan for and control costs. In the Eagle Ford Basin, CDM Smith developed a construction and quality control program for an operator's assets. This program identified needed repairs, improved asset and facility integrity, reduced overall operational costs and enhanced long-term facility operational use.

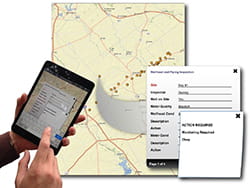

Inspect existing impoundments and water storage facilities quarterly. Continuing maintenance at your sites is important. For one developer, our team used a specially developed iPad app to note current conditions and overall integrity while making maintenance recommendations integrated with an asset management system. If you are interested in tapping into similar technology, ask yourself these five questions before investing.

Inspect existing impoundments and water storage facilities quarterly. Continuing maintenance at your sites is important. For one developer, our team used a specially developed iPad app to note current conditions and overall integrity while making maintenance recommendations integrated with an asset management system. If you are interested in tapping into similar technology, ask yourself these five questions before investing.

Taking these approaches will not only financially benefit upstream operators as they emerge from market downturns, but they will also position oil and gas businesses for sustained water management and infrastructure development success in the future.

Interested in talking about your water management goals, asset integrity programs or any other challenges? Or do you want to learn more about our full range of solutions for the oil and gas market? Email our oil & gas team.