Disinfecting Pipeline with Ozone: Saving Water, Money, and Time

Following a Pseudomonas bacteria event in 2013, Denver Water, Clearwater Tech (CWT) and CDM Smith collaborated on a five-year study to explore using ozone gas as a disinfection alternative to chlorine-based methods. The team found using ozone gas is a safe and effective way to drastically reduce the time and water during most disinfection tasks. Since ozone is a much strong oxidant than chlorine, it has a strong disinfection capability and can kill even the most persistent bacteria. “It takes some pretty tenacious bacteria to survive 24 hours of exposure to super-chlorinated water, but they couldn’t survive 20 minutes of the ozone gas,” says CDM Smith discipline leader Christopher R. Schulz, PE.

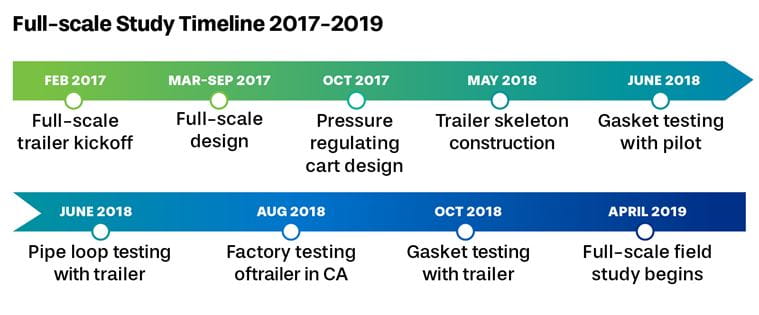

Beginning in 2015, pilot, demonstration, and full-scale scale studies were performed to test the practicality and effectiveness of the ozone gas disinfection process. In early 2017, the team designed a 15-foot trailer containing ozone generation equipment and a removable ozone off-gas cart for full-scale field testing. In May 2018, Denver Water contracted Five-R Trucks to begin building the skeleton trailer at Clearwater Tech’s factory in California. While the trailer was being built, the R&D team pilot tested the impact of ozone gases on pipe and gasket materials Denver Water uses for their distribution system pipelines. The gasket testing was performed again once the trailer was delivered in the fall of 2018. Full-scale field testing with the trailer ramped up in April 2019 and consisted of a side-by-side comparison of a chlorine-based power washing method.

"The full-scale field side-by-side comparison study completed in 2019 showed promising results with respect to increased passing rates during warmer months when temperatures in the distribution system rise above 15°C," says CDM Smith Environmental Engineer, Jill Vandegrift. "Ongoing studies through 2020 and 2021 will yield more information regarding the seasonal applicability of the ozone gas method when other Denver Water methods may struggle to maintain desired passing rates."

This R&D effort allowed us to equip Denver Water with solutions to improve inefficiencies and increase productivity, while also conserving water and saving money.

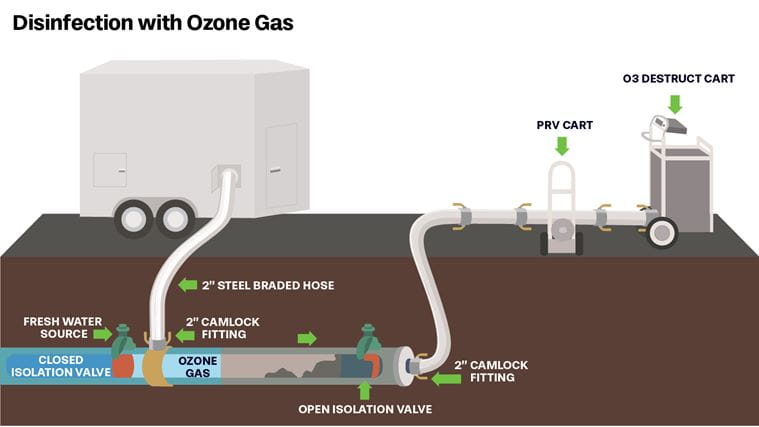

So how does the ozone gas system work? The trailer system pictured below contains oxygen concentrators, ozone generators, a regenerative air blower for ozone dilution and pressurization, and a mobile ozone destruct cart. Inside the trailer, gaseous ozone is generated and fed into a regenerative air blower to create a 500-2,000 parts per million (ppm) gaseous ozone stream. The pressurized stream is then injected into the water distribution main and held for about 30 minutes. The ozone concentration and disinfection time required to achieve passing results depends on the gasket materials, pipe size and level of infection. Before the gases are discharged to the atmosphere, the destruct cart converts the ozone to oxygen with manganese dioxide.

The study made strides towards incorporating the ozone gas method as part of Denver Water’s official arsenal of water main disinfection methods. Benefits of ozone gas-based methods include water conservation, time savings, and elimination of chemical transport. Alternative to chlorine based methods, the ozone gas method does not use water during the main disinfection step of the whole process. When considering that Denver Water must be publicly transparent with customers, any effort to serve as environmental stewards and conserve water can bolster confidence and trust in the utility. Since ozone gases have a wide range of applications, Denver Water is also considering using similar methods to disinfect storage reservoirs and large transmission mains.